We are the manufacturers of portable cabin for construction site office, work station, security cabin & toilets. We also do repair work for old portable cabin. We deal in shipping containers and FRP & PUFF cabin.

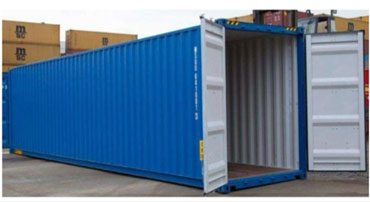

Specifications of Galvanized (G. I.) Containerized

Portable Cabin (Bunk House):

1 Size: Presently cabins of the following standard sizes are being offered off the shelf. However other sizes can also be manufactured upon specific orders. Our team of Engineers also provide valuable guidance in selecting and also in designing of special requirements.

2 Shell & Base Frame: The main bottom (Base) frame is part of an IS container framework on which 18 mm bison board or marine ply is mounted with vinyl flooring.

3 Side post: Specially formed 3.15 mm MS post section (Container type corner post to take a load of 10,000 kgs.)

4 G.I. Door: Door frame work by square pipe external wall made by Galvanized corrugated sheet & the inner wall will be decorated by laminated particle board & suitable locking arrangement.

5 Roof: The top of the cabin comprises Galvanized sheets, each sheet will have overlap on all sides & sheet will be fully welded using Co2 welding to prevent ingress of water.

Bottom shall be pre-laminated board.

Cavity filled with special density thick insulation to avoid overheating.

Air-gap shall be created in between the sheet & the insulation for further Reduction in thermal conductivity using special roof cooling system.

6 Welding: The containerized bunk house shall be of all welded steel construction using the latest method of MIG (CO2) argon shield gas.

7 Window: Sliding type powder coated window with grill & will be protected by weather shades.

8 Outer wall panel:Outer wall will made by Galvanized corrugated sheet.

9 Inner wall panel: 9 mm decorative laminated sheet shall screwed on the side wall on the internal. All vertical & horizontal corners shall be neatly finished off The roof shall be of 9 mm decorative laminated sheet with aluminum powder coated beading. The ceiling of the roof shall be suspended from inside an IS Container.

10 Insulation: Special quality insulation is used to maintain a cool interior.

11 Partition wall: All partition walls frame made out of 50 mm x 50 mm x 16 g sq.pipes 9 mm panelling of particle board on both sides of wall with concealed wiring & concealed switch socket board.

12 Electricals: All wiring shall be ISI mark of reputed make.

Switches shall be ISI mark

Concealed wiring shall be provided.

Main input plug adaptor for efficient & leak-proof flow of current.

M.C.B, ELCB shall b provided for additional safety.

Air-conditioning units may be provided wherever required.

Louvered exhaust fan for removal of foul air in the toilet area.

13 Furniture: As per the customer's specific requirement.

14 Painting: phosphating the cabin internally & externally & painting with coat of epoxy primer with two coats of epoxy top coat.

15 Site Preparation: The ground on which the portable cabin will be placed must be levelled and sufficiently hard to withstand the weight of the portable at the four corners. It is well advised to ensure that level is maintained.

Portable Toilet Block Specifications

1 BASE: The main bottom (Base) frame is a part of an IS container, framework on which 19mm Bison Board and marine ply mounted with vinyl.

2 ROOF: Top outer curved Galvanized plane sheet welded with M.S Frame structure Top inner decorated with partical laminated board of good quality.

3 ELECTRICAL: Quality electrical product conforming of ISI standard will be used.

4 WALL PANEL : outer wall will be of made by Galvanized corrugated sheet and inner wall will be decorated by water proof Bakelite sheet or hardner sheet.

5 DOOR: Outside door will be of Galvanized corrugated sheet and internal door will be of Marine Flush Door with Laminated or FRP door.

6 PAINT: phosphating the cabin internally & externally & painting with coat of epoxy primer with two coats of epoxy top coat.

7 INSULATION: Special quality insulation is used to maintain a cool interior.

TECHNICAL DETAILS FOR PORTABLE CABIN

1) Bottom Frames - The Bottom frame shall be made of pressed mild steel Sq pipe 3mm thik 100x50mm.

2 Stiffener Bottom - 100mmx50mmx3mm Rectangular pipe & 60mmx40mmx2mm Rectangular pipe.

3) Top main Frames - 60mmx40mmx2mm thick Sq. Pipe.

4) Stiffener Top - 40mmx20mmx18g Rectangular Pipe.

5) Side Corner Post steel - 125mmx125mmx3mm thick M.S. shall be made of pressed mild steel.

6) Side Wall Stiffeners - 40mmx20mmx18g Square pipe.

7) Paneling Outside - Specially formed galvanized corrugated sheets-18g.

8) Internal Wall Paneling - 9mm MDF board with decorative aluminum power coated strips or cement fiber sheets.

9) Roof Outside - Galvanized sheets -18g thick properly sloped and water tight.

10) False ceiling - 9mm Pre-laminated partical board(termite and dimensional proof)

11) Bottom Flooring - 18mm cement bonded fiber sheet (100% water, termite dimensional proof) with vinyl carpet of thickness 1.3mm.

12) Aluminum Window - Double shutter sliding aluminum powder coated window with 4mm glass for all windows safety grills form out side & monsoon shed on top of the windows.

13) Main Door - Constructed of rigid steel frame and Galvanized Corrugated sheet on the outside and 3mm Aluminum composited sheets (ACP) on the inside, door with standard hardware locks, door closer & handles.

14) Insulation - Rock wool density of 48kg/m(Side wall-30mm,Ceiling 60mm).

15) Writing & Electrical fittings - Wiring shall be concealed type with HPL cable make of ISI standard, All electrical fitting shall be220-240V, A/C-50h2 Tube LED 4feet, Bulkhead out side, Fan, switch sockets telephone points, LAN Point (As per customer needs). A/c Point (MCB), Earth Leakage Circuit breaker (ELCB) At the input junction.

16) Earthling - Earthling Point shall be provided for SAFETY.

17) Outside Painting - Phosphate the cabin and painting with two coat of industrial Epoxy Primer with Two Coat of industrial Epoxy PU Paint.

18) Legs - 4 inch height, Four legs at all four corners.

19) Partition Wall - MS Pipe stiffener with 9mm pre- Laminated Board with decorative aluminum power coated strips.

20) Hooks - Specially formed Hooks for Easy lifting and Shifting.